Published in2017-06-14

Stainless steel is not easy to rust steel, stainless steel, the main alloying element is Cr (Cr), only when the Cr content reaches a certain value, the steel corrosion resistance, stainless steel usually at least 10.5% Cr content.

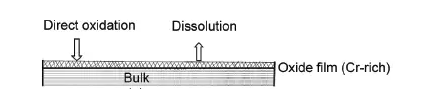

The corrosion mechanism of stainless steel for passivation membrane theory, namely its surface to form a layer of a very thin and fine and stable solid rich Cr passivation film, prevent oxygen to infiltration, continue to oxidation, so as to achieve the ability of corrosion prevention.

Diagram of passive film formation on the surface of stainless steel

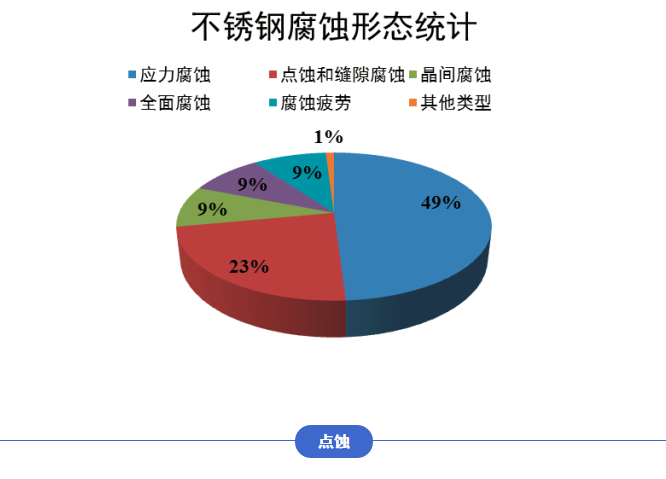

When the stainless steel surface appear brown rusty spot (point), big surprised: people think \"stainless steel is not rusty, rust is not stainless steel, is likely to be the problem of steel\".Actually, this is a one-sided error for a lack of understanding of stainless steel.If we can intuitive understanding of various types of corrosion of stainless steel, the face of stainless steel corrosion can have corresponding measures to reduce the loss.The combination with the engineering practice about several kinds of common type of corrosion of stainless steel, a brief introduction to the corresponding anti-corrosion measures, and focus on stainless steel stress corrosion causes and prevention measures.

More stainless steel corrosion damage is the local corrosion damage, the most common (9%) of the intergranular corrosion, pitting (23%) and stress corrosion (49%).

Pitting is a kind of very dangerous local corrosion, holes and then sharply on corrosion phenomenon, serious when can cause perforation.The influence factors of pitting corrosion mainly include:

1, Cl -, Cl - make stainless steel passivation membrane local failure, cause this part first corrosion;

2, temperature influence, the higher the temperature, the faster the corrosion;

Contaminants adhered on the surface of the 3, prevents the oxygen flow.

For example, in the daily life of stainless steel (201 or 304 stainless steel in the majority) sink is pitting occur frequently.If some acid or salt substances contained in the water tank is not timely processing, will lead to pitting corrosion of stainless steel water trough.

Pitting corrosion phenomenon of stainless steel water trough

Preventive measures have the following a few:

1, prevent the Cl - adhesion;

2, reasonable surface treatment, form a stable passive film;

3, and the choice of Cl - strong corrosion resistant material (such as adding Mo 316 l stainless steel).